Sales Hot-line:

Sales Hot-line:

trade news

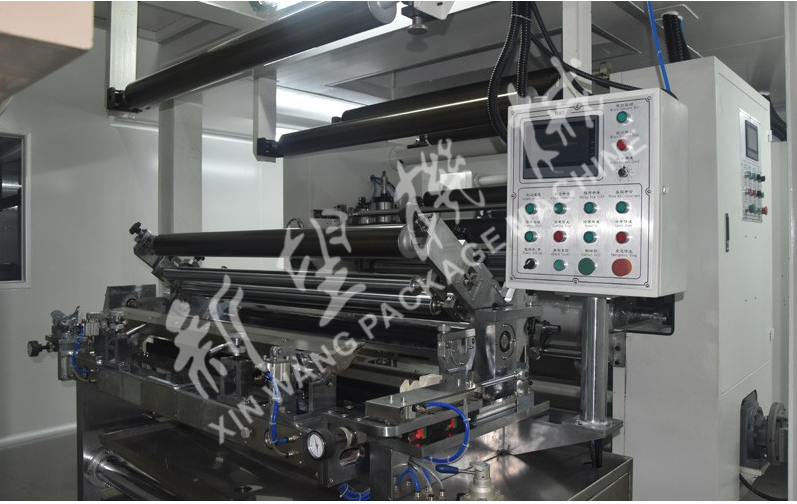

As a kind of gravure coating, the micro-cavity coating machine belongs to roller coating. The difference between it and gravure coating mainly lies in the gravure roller diameter, back roller and the movement direction of gravure roller and substrate. With the increasing market demand for high functional films and the popularization of wet coating technology, the micro-cavity coating machine will be widely used in the high-end functional film deep processing industry.

The principle and process of the micro-cavity coating machine: the micro-cavity coating method uses a gravure roller. The surface of the gravure roller is installed on the bearing, and part of it is immersed in the feed plate. The rotating shaft takes up the coating. After being quantified by a flexible rigid scraper, the coating liquid is taken away from the reverse moving substrate to achieve uniform thin coating.

The rotation direction of the gravure roller of the micro-cavity coating machine is opposite to the movement direction of the film base, which means that the film base is pressed onto the gravure roller without the back roller. If the running direction of the film base is the same as that of the gravure roller, the material will separate, part of it will go to the film base and part of it will stay on the gravure roller.

What are the advantages of micro-cavity coater? Today, let's talk to you:

1. A thin coating can be applied to a thin material. Because there is no back pressure roller, there are no offset printing, wrinkles and other defects on the coating surface;

2. Because the scraper touches the anilox roll lightly, the wear of the scraper and the anilox roll is relatively small;

3. The micro-cavity roller has small diameter and light weight. It is convenient to replace the micro-cavity roller with different coating amount;

4. Reverse coating can obtain relatively flat coating, and the coating amount is evenly distributed.

Application of micro-cavity coating machine: shading film, various optical films, lithium battery materials, various composite tapes, film, protective film, etc.